Sanwa Hydrotech Corporation develops, manufactures and sells process pumps including metallic seal-less magnet drive pumps, multi functional pumps for slurry application.

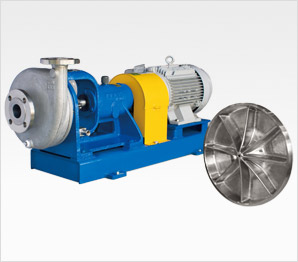

High Performance Slurry Pumps

For slurry protection applications (no breaking down of the solid content)Through Pump

"Through Pump" Type PS, which can transport slurry without breaking down the containing solids, is designed and manufactured on the basis of a non-traditional theory -Vortex Induction Theory. The crystalline material doesn't contact the impeller directly and will not be broken down or damaged. And a slurry comprising solid under the size of the pump discharge can be pumped smoothly.

The impeller blades are arranged in a radial fashion, and the clearance between impeller and casing has been designed with sufficient consideration.

Therefore, there's no need to worry about the big solids, crystalline materials or slurry in a fiber fashion twining around the impeller.

With no extra protrusions on the inner surface of casing and suction bore being made particularly bigger, the liquid can smoothly flow through the suction in a relatively slow speed, therefore nothing like crystal fragmentation caused by contact between impeller and the liquid or so would ever occur to break or damage the solids.

Variable speed motor or inverter motor can be utilized to adjust pump capacity and total head, therefore discharge valve is unnecessary. Optimum operation can be carried out in accordance with the operation rate of the process.

FAQs

- Q1: What's the purpose of developing "Through Pump"?

-

A1:

It has been developed for transportation of solids. Below are the 2 main features of "Through Pump".

- Smooth transport of slurry with no solid clogging.

- Transport liquid with almost absolutely no breaking-down or damage to the solids or the crystal.

- Q2: Can "Through Pump" transport liquids without clogging or breaking down of solids?

-

A2: Yes. Solids transport is possible with "Through Pump" because of its following features.

- The clearance between the casing and the impeller is almost the same dimension as the discharge thus the solid is less likely to be blocked inside the pump.

- A circular casing with a big radius at the discharge protrusion can lessen the breaking down to solids.

- With a particularly wide-bore suction slowing down the inlet velocity of the liquid, it's less likely that the solids would be damaged by contacting with the impeller.

- The radial-blade impeller creates vortexes (the function is similar to the bottom of a washing machine) to pump liquids. In addition, because the impeller is outside the water course of the casing and retracted to the case cover, the solids seldom pass through the internal part of the impeller. Furthermore, wearing of the impeller caused by solids is very small.

- Q3: Specific examples of the supplying record (and the reason why the users chose it)

-

A3:

- Resin pellets, PET bottle resin (to prevent clogging inside pump)

- Pharmaceutical intermediates slurry (to pump it to a centrifugal separator or a filter without breaking down of it)

- Rubber pieces (to recovery them from a pit)

- Q4:Supplying record for solid transfer

-

A4:

[Chemical Industry]:

Various organic slurry, various inorganic slurry, resin pellets/ chips, latex, rubber pieces

[Fine Chemicals]

Pharmaceutical intermediates slurry

[Recycling]

PET bottle resin

[Other] food

Raw salt, rice, soy, fish meat - Q5: Is vertical pump available for this type?

-

A5:

Yes. Please contact us for inquiries of Vertical PS pump.

※The pictures below is an example of a vertical submersible pump we manufactured for the application of rubber powder recovery.

Main Specification of "Through Pump"

Product specification

| Pump Type | PS |

|---|---|

| Total Head (m) | 40 |

| Maximum Capacity (L /min) | 3000 |

| Maximum Temperature (℃) | 180 |

| Minimum Temperature (℃) | -20 |

| Maximum S.G. | 2 |

| Maximum Viscosity (mPa・s, cP) | 500 |

| Design Pressure (MPaG) | 1 |

| Bore [Suction x Discharge] (mm) | 40×20 to 200×200 |

| Piping Connection (Flange Type) |

JIS 10K RF ASME 150LB RF |

| Impeller Type | radial-blade |

| Motor Output | to 75kW |

| RPM | to 2400 |

| Material | 304SS 316SS Alloy20 Has-C equivalent, etc. |

Construction

|

|

| 1.IMPELLER 2.CASING 3.CASING COVER 4.SEAL BOX 5.INSERT HOLDER 8.SHAFT 8B.COUPLING KEY 8C.BEARING WASHER 8D.BEARING NUT 8E.SET SCREW 9.SLEEVE 9A.O RING 10.BEARING HOUSING 11A.BEARING COVER(A) 11B.BEARING COVER(B) |

13.DEFLECTOR RING 17.OIL GAUGE 18A.BALL BEARING(A) 18B.BALL BEARING(B) 19A.DUST SEAL(A) 19B.DUST SEAL(B) 20.MECHANICAL SEAL 22.PIN 33.GASKET 33A-1.GASKET(THREE SHEET PACKING) 33A-2.GASKET(THREE SHEET PACKING) 33C.O RING 33D.O RING 35.AIR VENT |